November 25, 2024

Present status of air filtration system in domestic pig farms

At present, domestic large-scale boar stations and original breeding pig farms are basically equipped with air filtration systems. Based on the fact that pig farm air filtration systems can keep the incidence of pigs in high-risk areas low, the industry has begun to pay attention to the air filtration epidemic prevention system.

Transmission routes of pathogens in animal husbandry

The main transmission routes are inter-field transmission and intra-field transmission. Almost all pathogens can be transmitted between fields through aerosols, mainly considering the pathogen load and meteorological conditions. As long as aerosols can be formed and are infectious, inter-field aerosol transmission can occur. Infection prevention is mainly to prevent inter-field transmission. Non-diffusion and detection and elimination are mainly to prevent intra-field transmission.

Viruses are transmitted in the form of vectors

Usually, the diameter of bioaerosol and dust particles is 0.3~5.0μm

SIV (swine influenza virus): 0.08μm-0.12μm

PRRSV (blue ear disease): 0.05μm-0.065μm

FMDV (oral disease virus): 0.022μm-0.03μm

PCV2 (porcine circovirus type I): 0.017μm-0.022μm

PRV (pseudorabies): 0.15μm-0.198μm

African swine fever: 0.175μm-0.2150μm

As can be seen from the above, the diameter of viruses is very small, but in general, viruses and bacterial pathogens can only be transmitted by attaching to carriers, mainly in the form of bioaerosols. The diameter of common dust particles or bioaerosols in nature is usually 0.3μm~5.0μm. Air filters can filter virus carriers, thereby playing a role in virus filtering.

Filtration principle

Air filters do not directly filter viruses or bacteria. What they actually filter are the transmission media of pathogens, namely dust particles or other aerosols. Pathogens themselves cannot spread through autonomous flight and need to be attached to a medium to spread. The diameter of this medium in nature is usually 0.3~1 micron, so air filters also filter these 0.3~1 micron particles to intercept bacteria-carrying particles.

At present, domestic large-scale pig farms are equipped with air filtration systems to filter particles attached with these viruses to reduce the risk of virus transmission.

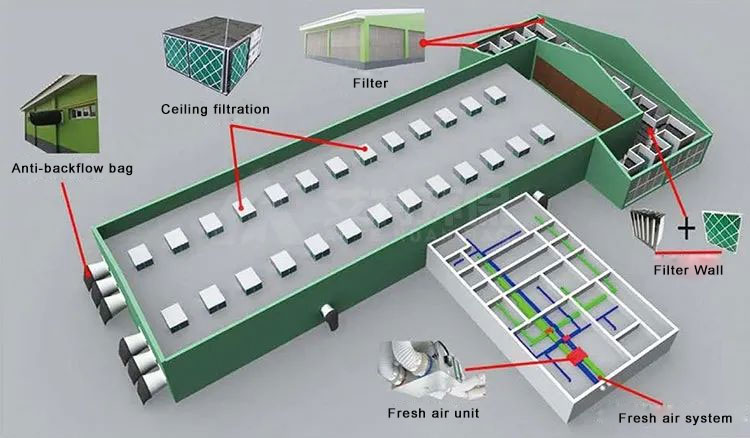

Currently, common ventilation and filtration methods include negative pressure ventilation and filtration, positive pressure ventilation and filtration, and balanced ventilation and filtration. The choice of ventilation and filtration method depends on the level of air cleanliness required in the pig farm. At present, the negative pressure ventilation solution has good cooling effect and relatively economical energy consumption, which is adopted by most large-scale pig farms in China.

▶In the entire pig house air ventilation system, two or three layers of filters are installed on the outside of the air filter to clean the pig house production environment and isolate the invasion and cross infection of mosquitoes, flies and rats.

▶The boar house generally uses G4 coarse-effect filter + W-type high-efficiency air filter to form the main filter wall. The main filter wall blocks airborne pig farm pathogens, and the purification efficiency reaches L9. The long-term purification efficiency of 0.3μm aerosols or particles is greater than 95%.

▶The ceiling filter system is installed on the pig house ventilation window for ventilation of pig houses in low temperature seasons under negative pressure ventilation mode.